The value of Craftsmanship

Stamps

Since its first production of postage stamps in 1866, Royal Joh. Enschedé has become the leading producer and supplier of postage stamps to over 70 countries. In almost 150 years of postage stamp production, the company has become a highly specialised and well equipped stamp printer that distinguishes itself through high quality and continuous innovation.

Royal Joh. Enschedé Stamps takes pride in its products. Customers wishes and requirements shape and inspire the stamps that are printed. All stamps are the result of intensive dialogue between the customer and the specialists within the company. The high quality of Royal Joh. Enschedé stamps is recognized and lauded all over the world. Realizing the importance of the customers issue dates, the company is fully committed to deliver the products according to specifications and planning.

Current Stamps & Innovations

Stamps’ pre-press is very advanced and completely digitalized. Since the production process is integrated with the banknotes’ pre-press department, many special design options and security features are available. Stamp printing at Royal Joh. Enschedé is possible in various printing techniques like (web)offset, silkscreen, foil and even intaglio or combination of these methods.

Whether it is gummed, self-adhesive, definitives, commemoratives, business mailer, sheetlet, roll, perforated, die-cutted or any other special demand you may need, Royal Joh. Enschedé has a solution to offer.

Royal Joh. Enschedé is known for its ability to supply stamps in a great variety of packaging materials, ready for use at the point of sale. The printing quality of postage stamps is the main feature appreciated and valued by stamp collectors all over the world. As a consequence, all of Royal Joh. Enschede’s stamps are conform the highest standard of printing available today.

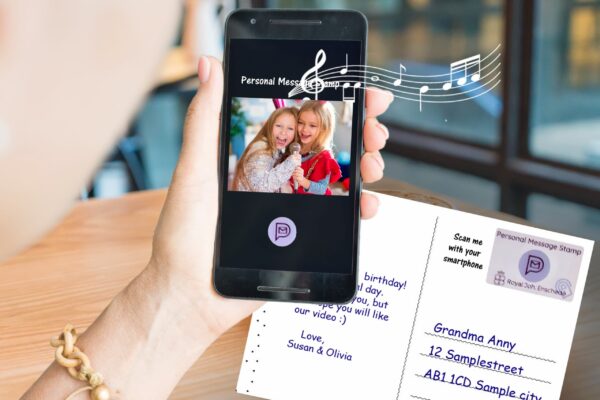

Continuous innovation in stamps is shown by the special bespoke stamps it produces in close cooperation with customers and suppliers. A ‘pop-up stamp’, a stamp with a book, special foils and holograms, 3D stamps, hidden features like music or a movie, stamps printed on silk – the sky is the limit.